HVAC Case Study

Torresan Estate

Climate Wizard, the optimal solution for temperature and humidity regulation

In 2007 Torresan Estate opened the doors to their environmentally friendly, state of the art, contract bottling facility situated in McLaren Vale which services the needs of the McLaren Vale Wine region and further afield.

The purpose built facility has 2 lines in operation with a capacity to bottle 14,000 cases of wine per 8 hour shift. With their brand new larger line in place, it is the first fully automated bottling line in the region capable of bottling over 14,000 bottles per hour in combination with the smaller premium line that has a capacity of 8,000 bottles per hour. Servicing the bottling facility are three finished goods storage areas including a primary 3,000 square metre warehouse, a secondary warehouse of 4,800 sqm and a brand new 4,500 sqm facility.

Contract Wine Bottling

Project Address

McLaren Vale, SA

Equipment

2 x Climate Wizard CW-80S Supercool

1 x Smart Climate Controller

Application

Warehouse Dry Store, finished goods

Project Requirements

Torresan Estate required a climate control solution for their expansive finished goods warehouse that delivered the below requirements:

- Minimal energy consumption

- Maintain targeted temperature within the warehouse between 18 – 20°C

- Maintain target temperature along the full height of the storage racks

- Maintain the Ambient relative humidity within the building at 65%

Project Deliverables

Two Climate Wizard CW-80S units were installed to achieve precise temperature and humidity control within the warehouse; enabling Torresan Estate to ensure consistent quality at a very low cooling cost.

Climate Wizard has the capability to maintain the 65% relative humidity specified. By pairing this with external cue points on the building, facilities management have full capability to control the environment to precise temperatures and humidity levels.

Selecting Climate Wizard over a traditional refrigerated air conditioning system meant there was not a requirement for an electrical upgrade to satisfy 71.5kW of input power compared to the two units only needing 20kW. In addition to this upfront cost reduction, Torresan Estate are seeing less energy consumption compared to if a traditional refrigerated air conditioning system was installed.

| Ambient DB (°C) | 36.4 |

| Ambient WB (°C) | 18.1 |

| Space Temp. (°C) | 18-20 |

| Relief Temp. (°C) | 20 |

| Model | CW-80S |

| No. of Units | 2 |

| Supply Air Temp. (°C) | 13.5 |

| Total Standalone Cooling Capacity (kW) | 105.2 |

| Standalone Cooling COP | 5.3 |

Results

Being able to maintain optimal conditions within the dry store for finished goods all year round, particularly during periods of extreme heat, added another dimension to the exceptional level of service provided by Torresan Estate to its customers. This gives greater assurance to maintaining the quality of the wine being bottled and stored.

Climate Wizard Supercool capability is not affected during periods of extreme heat, where ambient dry bulb temperatures reach up to 50oC.

Table 1 outlines the energy savings for the installation, extrapolated over a 12 month period. Input power savings for the installation have been calculated as per Table 2.

Table 1

| Energy consumed by equivalent refrigerant system (kWh) | 82,467 |

| Energy consumed by 2 x CW-80S (kWh) | 29,531 |

| Energy saved (kWh) | 52,936 |

| Energy saved ($)^ | $10,587 |

^Based on an average price of $0.20 per kWh estimated by Seeley International.

Table 2

| Input power of equivalent refrigerant system (kW) | 71.5 |

| Input power of 2 x CW-80S (kW) | 20 |

| Power saved (kW) (electrical demand) | 51.5 |

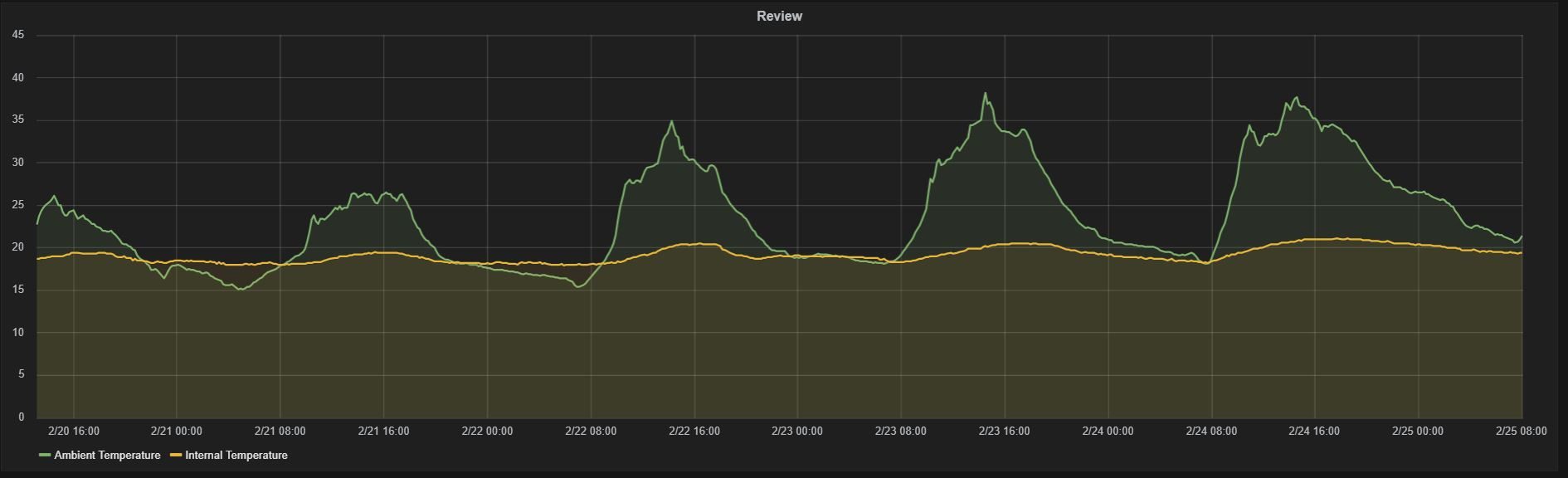

Below is a snapshot showing how Climate Wizard successfully maintains target temperature within the warehouse during periods of extreme heat.

HVAC Case Study Overview

Industry

Wineries

Country

Australia

Region

South Australia

Technology

Indirect Evaporative Cooling

Application

Stand-alone Cooling

Brand

Climate Wizard