HVAC Case Study

Bluetree Group Print Shop cooling

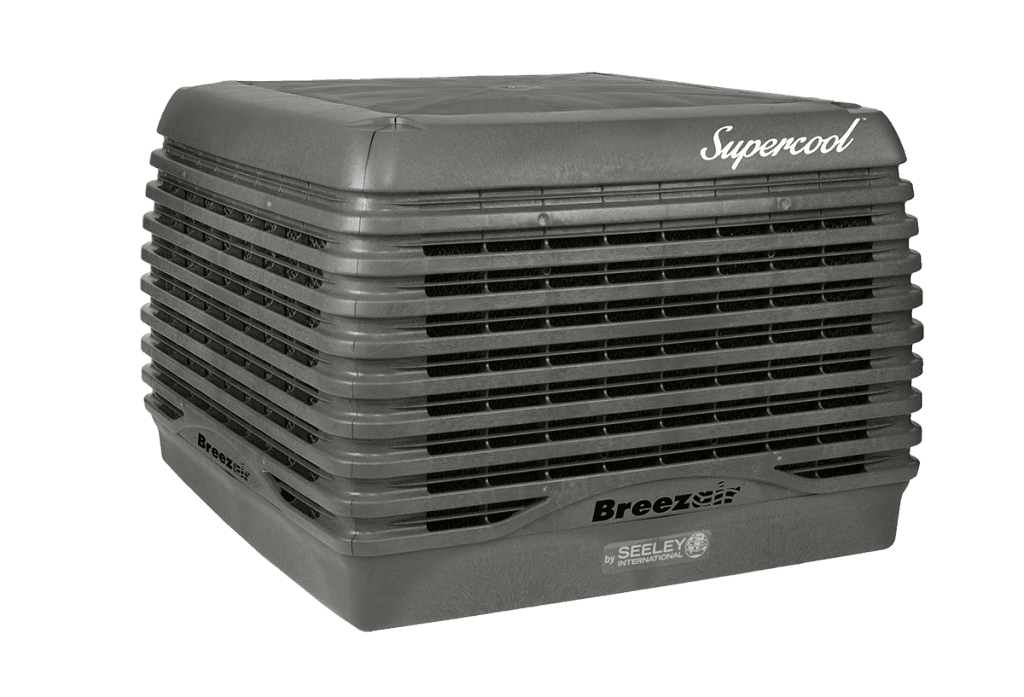

Breezair evaporative cooling, cost-effective solution for overcoming heat gains from printing presses

Bluetree needed a solution for cooling their print shop, while reducing evaporation of solvents. They found the right solution in Breezair evaporative cooling.

The problem

One of the UK’s fastest growing print shops is no longer counting the cost of keeping cool during the British summers. In 2017, Bluetree group had an evaporative cooling system installed. This system maintains an optimal indoor climate for plant and operators throughout the year. Their building hosts several printing presses.

When a pattern began to emerge of persistent plant breakdowns during warm weather periods, operations staff raised concerns that stifling conditions around the main production lines would affect run rates and prove detrimental to morale.

Facing shop floor temperatures well above 30°C and dead spots spread across a considerable area of the factory, the challenge was to find an effective solution with low running costs.

The cooling solution

To counter these issues, eight Breezair TBS580 Evaporative Coolers and two Encon 75UD Roof Fans were installed by Encon Air Systems, ensuring that a temperate climate is maintained in business critical areas.

Jim Swain, Operations Director at Bluetree had grappled with the same issue at the firms’ previous facility before moving to the current 100,000 square foot production facility in Rotherham. He said:

“We knew that the only cost-effective solution for overcoming heat gains from the presses would be evaporative cooling. It was essential that the cooling system be up and running for the start of summer, in order to prevent system down time and back logs due to excessive temperatures on the shop floor. With the Breezair system, we can continue to meet tight turnarounds without being dogged by breakdowns.”

Matt Dawson, Projects Manager at Encon Air Systems commented:

“We deployed the Breezair units into the corridors between machines to ensure optimal distribution of air. As wet bulb temperatures in the UK rarely get above 20°C, we are confident this technology will continue to delight customers and deliver energy efficiency savings over conventional air conditioning.

In this instance, the MagIQtouch touch screen controller provided an easy to use, central point of control for Bluetree to monitor conditions on the shop floor.”

Are you curious to know more about Breezair Evaporative cooling? Click here to know more.

Watch this video to understand Breezair Direct Evaporative Cooling technology.

HVAC Case Study Overview

Industry

Industrial / Manufacturing

Country

United Kingdom

Region

South Yorkshire

Technology

Direct Evaporative Cooling

Application

Stand-alone Cooling

Brand

Breezair