Optimising Industrial Temperature Control with Indirect Evaporative Cooling

- Australia, Europe, Asia, Africa, Americas

- Commercial

- Sustainability, Cooling

Cooling Industrial and warehouse facilities

In the pursuit of energy efficiency and enhanced operational performance, industrial and warehouse facilities are increasingly looking at innovative temperature control solutions to lower operational costs. The Climate Wizard’s Indirect Evaporative Cooling (IDEC) technology, also known and referred to as M-Cycle Indirect Evaporative Cooling, is ideal for delivering adequate temperature control and optimal air quality in warehouses and factories. This innovative approach offers a plethora of benefits, including reduced carbon emissions, reliability, and substantial energy savings of up to 80% lower when compared to refrigerated systems performing the same duty.

The Benefits of Indirect Evaporative Cooling

Enhanced Energy Efficiency

The energy efficiency of IDEC systems can further be enhanced by coupling them with Air Handling Units (AHU). This integration can lead to further energy reduction, either by pre-cooling the AHU or boosting the efficiency of direct expansion (DX) or variable refrigerant flow (VRF) systems in supplementary applications. Energy saving is essential not only for reducing running costs but also supporting locations where power availability is an issue, or in industrial plants that need to reduce peak time energy consumption.

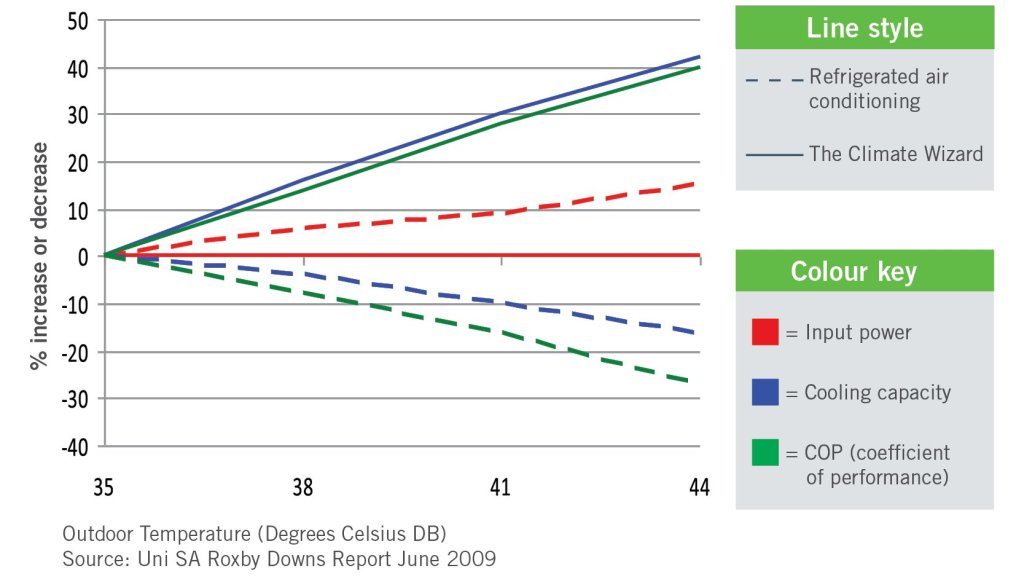

It is important to also note that all indirect evaporative coolers’ performance increases as temperature rises, in direct contrast to conventional air conditioning system that consume much more power to maintain the same levels when temperature increase. The chart below illustrates this.

The Climate Wizard vs refrigerated cooling capacity and COP as temperature rises

The solution – A single CW-160 that delivers 11,800 l/s (25,000 cfm) into the machine shop via ducts arranged internally, across one wall of the building. Exit paths for the existing air were installed on the opposite side of the building. This allows the fresh cool air to purge away the contaminated air.