HVAC Case Study

Brawo: cooling manufacturing facilities with Breezair evaporative cooling

Improved productivity and working conditions with Breezair Evaporative Cooling solution at Brawo

Brawo is a historic company from Valcamonica and part of the Umberto Gnutti holding. Based in Pian Camuno, it operates two plants and employs around 340 people. The company specializes in hot stamping and machining of non-ferrous materials.

Background

Brawo is a company specialized in hot stamping and mechanical processing of non-ferrous materials, particularly brass and aluminum alloys. Although the facility had been equipped with an evaporative cooling system for over 18 years, a significant rise in internal temperatures was observed—especially during the warmer months. This led the company to reassess its cooling strategy and implement a targeted solution aimed at restoring optimal indoor conditions. The focus was placed not only on lowering temperatures but also on ensuring proper micro-ventilation, achieved through a controlled exchange of clean, filtered air from the outside.

The solution

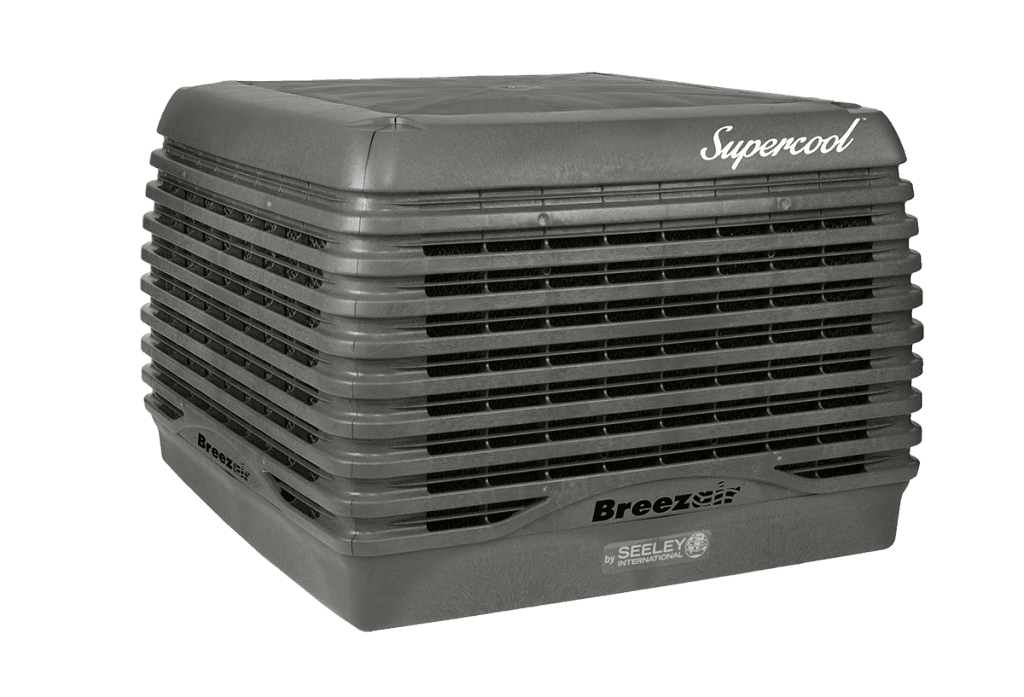

Italkero previously installed 22 Breezair coolers at Brawo, operating efficiently for 18 years. Looking to upgrade and enhance performance, the company turned to Italkero to explore potential solutions. Italkero has been importing and supplying Seeley International products for over 25 years. After conducting thorough inspections and temperature measurements, they determined that the existing system was no longer adequate to handle the increased external temperatures and the additional heat generated by the workstations. The new project involved replacing the outdated equipment with modern, energy-efficient, digitally controlled units. In addition, it was decided to increase the number of cooling units to a total of 30. This would have ensured sufficient air exchange capacity and optimizing the temperature differential achievable with this technology.

Results

The objectives set for achieving optimal internal microclimatic conditions have been successfully met. To date, during the warmer months, the average indoor temperature consistently remains around 27–28°C. Thanks to the digital control system of the coolers, it has been decided to divide the installation into 4 zones, each comprising approximately 7–8 units. This zoning allows for more precise and efficient management of each area. Throughout the project, there was excellent collaboration among all parties involved. Upon completion, Italkero thoroughly tested and verified the system’s performance, confirming to achieve all project goals and expectations.

Download the Case Study

More info on Breezair can be found visiting the Breezair page on our website.

To learn more on Breezair’s benefits, you can watch this video.

HVAC Case Study Overview

Industry

Industrial / Manufacturing

Country

Italy

Region

Technology

Direct Evaporative Cooling

Application

Stand-alone Cooling

Brand

Breezair