HVAC Case Study

KUMA - Furniture industry air conditioning

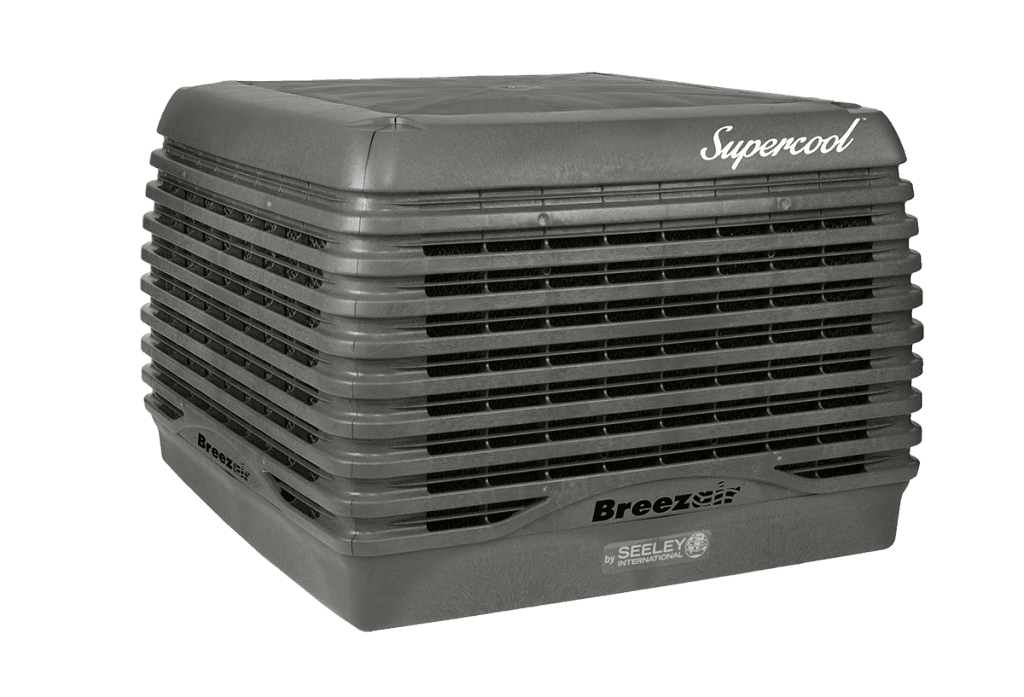

Ineffective Ventilation System Replaced with Energy-Efficient Breezair Furniture Industry Air Conditioning

KUMA is a Danish-Romanian company, a subsidiary of Kuma AS in Denmark in 1998. KUMA Romania has consolidated its leading position in the production and export of high-quality bathroom and kitchen concepts, merging functionality with Nordic design and sustainability.

Background

The production section is housed in a 6-meter-high hall constructed with sandwich panels. In the casting area, the manufacturing process generates significant heat. Meanwhile, the finishing section is impacted by both elevated temperatures and high humidity levels, along with the presence of volatile organic compounds (VOCs). The hall features polycarbonate skylights on the roof. Although an air treatment system was installed from the outset, it has failed to perform adequately, leaving worker comfort compromised.

In the search for a more effective technical solution, adiabatic cooling was considered due to its promising advantages. As a result, WEST AIR were invited to propose a suitable solution.

The solution

In this application—marked by a significant thermal load, high humidity, and airborne volatile compounds that made the production environment difficult to work in—adiabatic cooling proved to be the definitive solution. At the time, the adiabatic cooling concept was still in its early stages in Romania. As such, our proposal to implement Breezair cooling units was initially met with skepticism. The idea of cooling an industrial hall using mains water as a refrigerant seemed implausible, as later acknowledged by Ms. Camelia Olesen, Executive Director of Kuma Romania.

“As a new and unfamiliar cooling technology, I initially regarded WEST AIR’s proposal with skepticism.

The idea of cooling air using “plain” water rather than traditional refrigeration units seemed, at first, like an overly simplistic marketing claim. However, I was struck by the confidence and enthusiasm with which the solution was presented, as well as by WEST AIR’s strong track record and solid references.

These factors ultimately convinced us to proceed with their proposal—while also ensuring that appropriate safety measures were clearly outlined and agreed upon in the contract.”

Ms. Camelia Olesen, Executive Director of Kuma Romania.

The results: Breezair as perfect solution for furniture industry air conditioning

“The installation was completed within two weeks—cleanly and flawlessly.

In the end, all our initial doubts were dispelled the moment the system was commissioned. Although our production areas were previously equipped with a ventilation system connected to an AHU, it proved ineffective during the summer months, when indoor temperatures consistently exceeded comfort levels.

The Breezair installation delivered fresh, cool air without issue, even on the hottest days of last summer. In fact, the indoor temperatures achieved were even lower than we had anticipated.

We are confident that we made an excellent decision and fully intend to implement the same cooling system in other production areas within the next two years.”

Camelia Olesen, Executive Director, Kuma Romania

The initial installation, which included 5 Breezair units, was later expanded with an additional 6 units. As a result, workers can now fully benefit from the comfort provided by a continuous supply of fresh, cooled outside air, with Breezair furniture industry air conditioning system.

More info on the installation can be found visiting WEST AIR official website.

More info on Breezair can be found visiting the Breezair page on our website.

HVAC Case Study Overview

Industry

Industrial / Manufacturing

Country

Romania

Region

Technology

Direct Evaporative Cooling

Application

Stand-alone Cooling

Brand

Breezair