Evaporative cooling vs air conditioning

Evaporative cooling has many benefits if compared with conventional air conditioning, but also a few limitations. It is important to know its characteristics in order to specify it for the right applications and installations.

Let’s see all differences in details!

Traditional Air Conditioner

How it works

- Air conditioner removes heat and moisture from air

- The same air is continuously circulated in the building and through the air conditioner unit

- Where fresh air component is present, more energy is required compared to evaporative cooling systems

- Air is filtered as it is returned to the air conditioner

- Air conditioner uses chemical refrigerants to cool the air

Performance

- Temperature/humidity can be controlled

- Can remove moisture from air, reducing humidity

- Normally retains the biggest portion of air into the building– no to little fresh air added (adding fresh air component impacts on energy consumption)

- Cooling capacity negatively impacted by external temperature – the hotter the outside air, the less efficient the air conditioner

- High energy bills when installed in huge buildings

Evaporative Cooling

How it works

- Cools air by evaporation – only uses water and electricity to run

- Cool, fresh filtered outside air is continuously supplied to the building, with low energy consumption

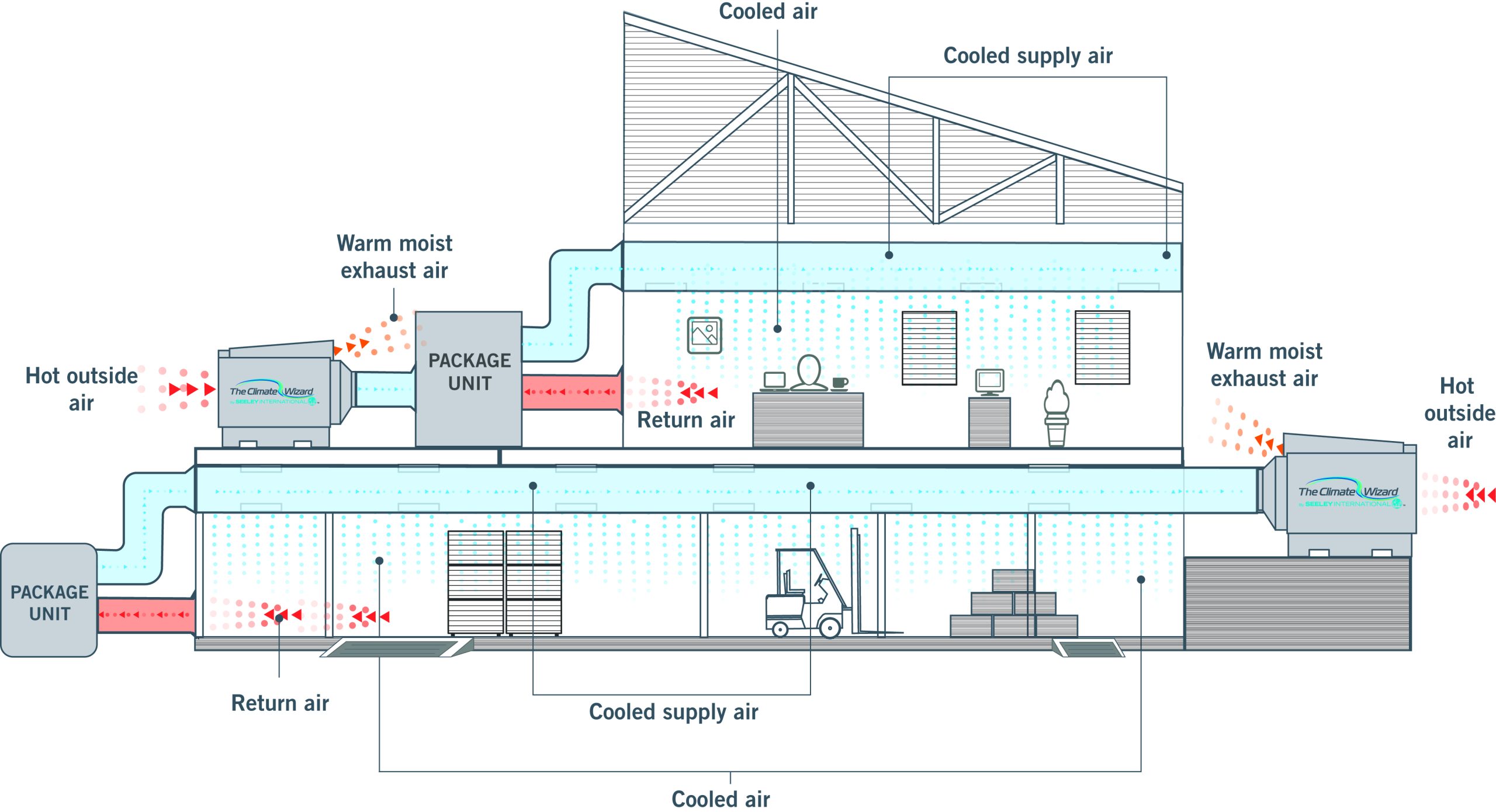

- Cool air is distributed throughout the building through ducts

- Normally higher airflow than traditional air conditioner

- Exhaust air is continuously removed from the building, through doors, windows or extract systems

Performance

- Temperature/humidity can be controlled by smart sensors

- High volume of cooled outside air supplied to building with high COP/EER

- Improving Indoor Air Quality (IAQ), by supplying 100% fresh outside air and high ventilation rate

- Cool air contains the same amount of moisture (for M-cycle indirect evaporative cooling / adds little moisture for direct evaporative cooling)

- Cooling capacity positively impacted by external conditions – the hotter the outside air, the more efficient the evaporative cooler

- Low energy bills when installed in huge buildings

- Thanks to its characteristics it can be installed for cooling open/semi-open areas

M-cycle Indirect Evaporative cooling technology can be coupled with a conventional A/C system for greater energy savings and for combining benefits of the two technologies.

Top 10 benefits for evaporative cooling compared to refrigerated air conditioning

Here is a guide of the top 10 most important benefits to look for when choosing between an evaporative air conditioner or a refrigerated air conditioner.

The main reason that evaporative cooling is so energy efficient is that the only power-consuming components are the motor for the fan, the control module, and a small water pump.

That means some evaporative cooling products can use 82 % less (1) energy than direct expansion air conditioning. That’s a huge saving and a great opportunity, if you consider that an average industrial air conditioner costs so much to install and maintain that often businesses have no A/C installed at all.

Fresh air is a major benefit of evaporative air conditioning, supplying 100% fresh, cool, outside air, all while delivering superior energy efficiency compared to a refrigerated equivalent. Indoor Air Quality is improved and impurities/pollens are filtered while passing through the pads – a bonus for allergy sufferers.

Evaporative air conditioners use far less electricity, therefore less fossil fuels such as coal and natural gas. You will also be surprised to know that evaporative coolers use less water than conventional air conditioning, if you consider water used to produce the electricity that evap is saving. Investing in a premium evaporative air conditioning product will not only deliver lower running costs but will also reduce energy demands and lower the carbon footprint of a factory or warehouse as a result.

A carbon footprint is the total amount of CO2 dispersed into the atmosphere and generated by our energy consumption (2). When measuring a carbon footprint, it’s the amount of carbon dioxide directly or indirectly produced. The carbon footprint is a method of determining someone’s environmental impact.

According to United States Environmental Protection Agency (US EPA) electricity production generates the second largest share of greenhouse gas emissions, in total 25 % of 2019 greenhouse gas emissions (3). If an industry appliance uses a low level of electricity, it minimizes the environmental impact.

Every time a customer chooses an evaporative vs a direct expansion cooler, the benefits for the environment are significant. In a location like Madrid (Spain), Breezair TBSI 580 evaporative cooler produces 86% carbon emissions less, if compared with refrigerated systems (4).

If we combine the low carbon footprint with the superior Indoor Air Quality, evaporative cooling can be considered one of the most efficient technologies in the market.

The comparison between evaporative and conventional direct expansion air conditioning is just as significant when it comes to the impact on the electrical grid. Evaporative coolers’ performance improves when heat is at its highest, consuming the same amount of power as temperature rises, therefore increasing COP/EER.

All Seeley International’s evaporative coolers are embedded with Water-Management system to check water quality and ensure a wise use of it. Moreover, evaporative coolers consume less water than conventional A/C, if we consider water used to produce the electricity that an evaporative cooler saves.

Easy and regular service by a qualified technician after each cooling season will ensure that an evaporative air conditioner continues to run at its peak efficiency while maintaining low running costs.

Seeley International’s network of approved contractor makes maintenance so easy that you can rest assure to have the units performing at their best all the time!

Thanks to the versatily and adaptability of our M-cycle indirect evaporative cooling models, they can be coupled to conventional A/C units in pre-cooling to act in the fresh air portion of Air Handling Units or in supplementary cooling to act in the air recirculation component of the chiller.

Seeley International evaporative coolers are the best in the market in terms of quality, robustness and durability. We have been manufacturing evaporative coolers for more than 50 years and have premium warranty conditions that prove the quality of all our products.

References

- Seeley International’s running costs comparison is a calculation based on assumptions including Building dimensions 1000m2 floor area x 6m high; Cooling time 12hrs/day, 6 summer months/year; Indoor temperature 22°C; Building heat load 100W/m²; Rooftop Unit – Fresh air 1,170 l/sec (20%); Rooftop Unit -COP 3; External ambient conditions based on Typical Meteorological Years (TMY) for Madrid (Spain); Power cost 0.11 €/kWh; Water cost 1.5 €/m³; Electricity Generation CO2 equivalent 340gCO2eq/kWh. The comparison should be used as a general guide only.

- The Nature Conservancy – Calculate Your Carbon Footprint

- EPA – Sources of Greenhouse Gas Emissions

- Seeley International’s running costs comparison is a calculation based on assumptions including Building dimensions 900m2 floor area x 6m high; Cooling time 12rs/day, 6 summer months/year; Indoor temperature 25°C; Internal building heat load 13.5kW; Fresh air 4500 l/sec; Refrigerated A/C COP 3; External ambient conditions based on 2018 Madrid (Spain) weather data; Power cost 0.11Euro/kWh; Water cost 1,5Euro/kl; Electricity Generation CO2 equivalent 340gCO2eq/kWh. The comparison should be used as a general guide only.