Indoor air quality on top of mind for business owners and facility managers

Since the COVID-19 outbreak, there is unprecedented demand from businesses for fresh, cool air. We all acknowledge outside air as a core component of healthy and comfortable buildings. Evaporative cooling can be the best ventilation system for factories, warehouses and businesses all around Europe.

Evaporative Cooling only uses water and little electricity to cool outside air. This way, evaporative cooling never recirculates indoor stale air, same as traditional air conditioners do. Who wants to breath someone else’s air? No one!

Evaporative cooling as hyper-efficient ventilation system

Seeley International is a global leader in evaporative cooling technology with offices all over the world, including Europe.

It is paramount for building owners to protect their employees and customers. How to better protect them than through the health benefits of fresh air? This needs to be done without sacrificing energy efficiency and comfort. For this reason, many consumers are switching from refrigerated or direct expansion cooling to evaporative cooling.

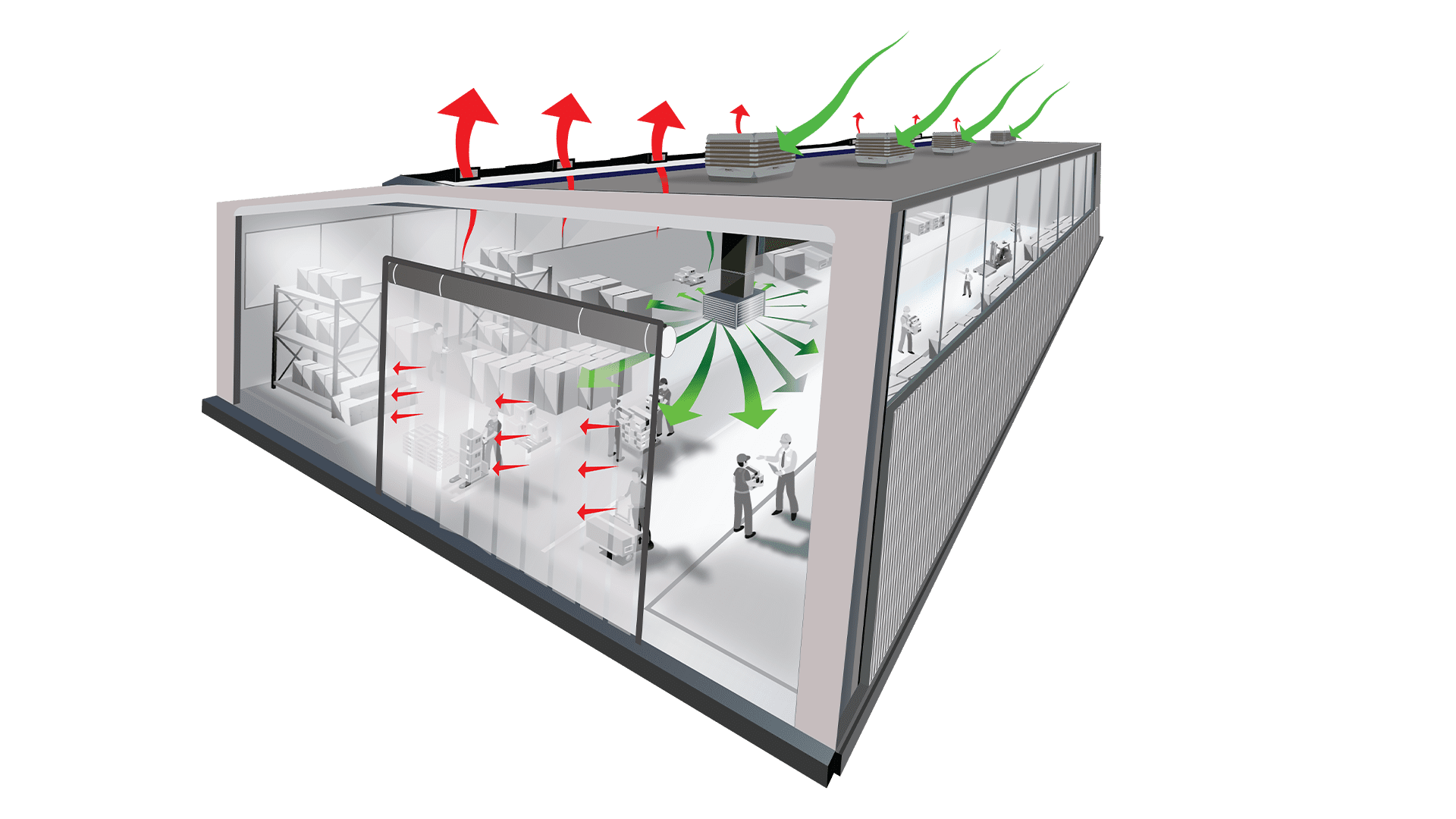

In this vision, Seeley International’s evaporative cooling technology provides a complete change of air every few minutes (6). In fact, the evaporative process relies on air flow, with cool air entering through ducts and then exiting through dedicated vents. Moreover, the cool air provided through such ventilation system is not stale or recycled, but 100% fresh. For all these reasons, it is the most efficient way to deliver cooled, outside air.

As a consequence, the challenge for many businesses in Europe, particularly with ever-changing weather is to maintain a comfortable indoor climate without compromising fresh, outside air.

Evaporative cooling remains the most beneficial form of ventilation system. The ability of evaporative air conditioning to supply 100% fresh, cool, outside air makes it the cooling option of choice for business owners and managers. Many of them nowadays are really serious about improving air quality inside their commercial and industrial buildings.

When it comes to healthy living in your workplace, everyone deserves the best. Evaporative air conditioning will let you breathe a well-deserved sigh of relief.

Climate Control solutions: evaporative cooling

Market leading evaporative cooling solutions by Seeley International can offer comparable comfort to direct expansion cooling, with superior energy efficiency and savings up to 86% on the running costs(7).

In this scenario, evaporative cooling remains one of the oldest and most beneficial forms of climate control. The ability of evaporative air conditioning to supply 100% fresh, cool, outside air is a growing choice for cooling industrial plants, storage facilities and many other businesses.

The importance of ventilation and Indoor Air Quality for businesses

REHVA (Federation of European Heating, Ventilation and Air Conditioning Associations) recently confirmed that ventilation measures are amongst the most important engineering controls in the infection control.(1)

Moreover, they suggest to increase ventilation rates and operation time of all air conditioning equipment, considering that the main recommendation is to always avoid recirculation, either centralized or at room level. Regarding this point, it is essential to switch air handling units with recirculation to 100% outdoor air.

More worldwide contributions:

The World Health Organization (WHO) recommends particular precautions. They include the avoidance of enclosed spaces with poor ventilation and to ensure good environmental ventilation in all closed settings (2).

Furthermore, the American Society for Heating, Refrigeration and Air-Conditioning Engineers (ASHRAE) is clear in its recommendation of the importance to increase in outdoor air ventilation of buildings (3).

Finally, leading academics have also highlighted the critical role of indoor air quality and ventilation. Shelly Miller, Professor Mechanical Engineering, University of Colorado Boulder has expressed this. “The safest indoor space is one that constantly has lots of outside air replacing the stale inside air … the more fresh, outside air inside a building, the better.” (4)

Experts agree that the HVAC industry has a critical role in the health of our buildings.

It is an endorsement for facility managers to increase the amount of outdoor air coming inside. This can prevent from recirculating the same stale indoor air over and over, when this air contains viruses and germs.

The most contemporary and relevant example of this is COVID-19 and its ability to transmit through small, airborne particles.

For this reason, there is no surprise that companies like Seeley International are seeing a rise of interest in evaporative cooling technologies. The market for delivering cooled outside air as efficiently as possible will continue to grow. This is even more true with the world getting warmer and demand for healthy buildings growing stronger.

References:

- https://www.rehva.eu/activities/covid-19-guidance.

- World Health Organization: Transmission of SARS-CoV-2: implications for infection prevention precautions.

- ASHRAE: Guidance for Building Operations During the COVID-19 Pandemic.

- The Conversation: How to use ventilation and air filtration to prevent the spread of coronavirus indoors.

- The Western Cooling Efficiency Center (WCEC).

- Based on published research articles, NATA Laboratory test results and publicly sourced data.

- Seeley International’s running costs comparison is a calculation based on assumptions including Building dimensions 900m2 floor area x 6m high; Cooling time 12rs/day, 6 summer months/year; Indoor temperature 25°C; Internal building heat load 13.5kW; Fresh air 4500 l/sec; Refrigerated A/C COP 3; External ambient conditions based on 2018 Madrid (Spain) weather data; Power cost 0.11Euro/kWh; Water cost 1,5Euro/kl; Electricity Generation CO2 equivalent 340gCO2eq/kWh. The comparison should be used as a general guide only.

- Climate Wizard Supercool (indirect/direct option) adds a small amount of moisture to the supply air.