HVAC Case Study

Northshore Apartments, Palm Beach

Challenges

- Corrosive Environment: The coastal location posed a significant risk of salt-induced corrosion, threatening the longevity of conventional AC systems.

- Limited Ceiling Space: Architectural constraints restricted ceiling cavity depth, making standard indoor unit placement unfeasible.

- Wardrobe Installation: Indoor units had to be installed within wardrobes, necessitating ultra-compact designs.

- Roof-Mounted Condensers: External units were required to be roof-mounted, introducing long piping runs that exceeded the limits of many conventional systems

Client Details

Rawcorp Pty Ltd is a respected construction company founded by Anthony Rigby and David Walton, combining deep expertise in project planning and delivery. Operating since 2005, Rawcorp holds open builder’s licences in Queensland and NSW, and has achieved Level One prequalification with the Queensland Government. Recognised by Master Builders and UDIA, the company is known for its collaborative, client-focused approach and commitment to balancing budget, time, and quality.

Serving South East Queensland and Northern NSW, Rawcorp manages diverse projects across corporate, government, commercial, and private sectors. With hands-on experience and adaptability, the team ensures tailored solutions and strong communication throughout every build. The directors remain invested in shaping the region’s future through thoughtful, high-value construction.

Project Requirements

To meet the unique demands of this project, the air-conditioning solution needed to:

- Withstand harsh coastal conditions with enhanced corrosion protection.

- Fit seamlessly within wardrobe cavities without compromising airflow or access.

- Support extended piping lengths between indoor and outdoor units.

- Deliver quiet, efficient performance suitable for high-end residential living.

- Offer a cost-effective installation that supports the developer’s financial goals.

System Design & Deliverables

The selected system featured:

• Black Fin Coil Technology: Enhanced anti-corrosion coating on coils to resist salt damage and extend operational life.

• Compact Bulkhead Units: At just 450mm deep, these units were specifically chosen to fit within wardrobe spaces without structural modification.

• Extended Piping Capability: The system supported long refrigerant piping runs, enabling flexible placement of roof-mounted condensers.

• Modular Configuration: Units were configured to allow zoned control and efficient servicing, minimizing disruption to residents.

• Energy Efficiency: High-performance inverter technology ensured optimal energy use across varying load conditions

Equipment Supplied

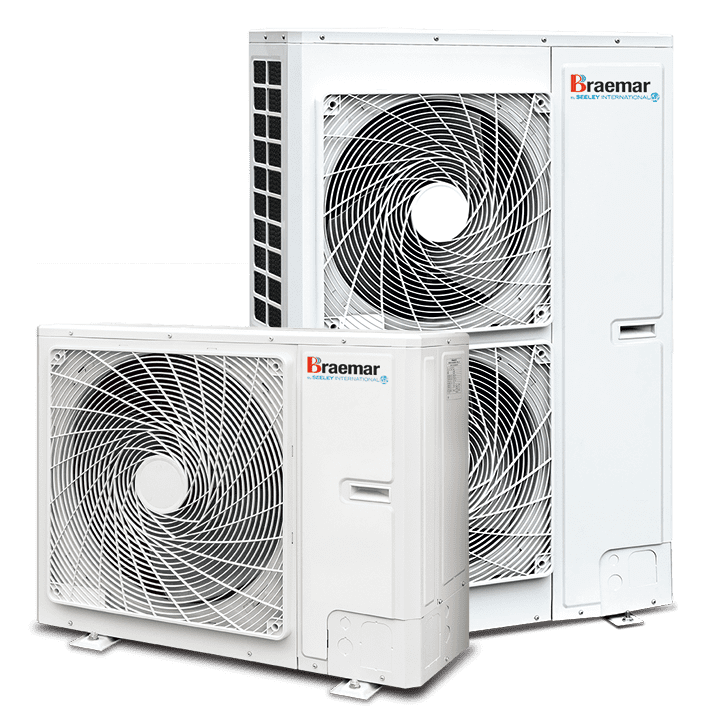

Outdoor Units:

• 54 x MCMX100D105B VRF ODU

• 15 x MCMX120D107B VRF ODU

• 1 x MCMX160D109B VRF ODU

Indoor Units:

• 69 x MDHXD1A High Static VRF Ducteds

• 53 x MDHXD1C Low Static VRF Bulkhead IDU

• 8 x MSHXD1L VRF HWS IDU

• 27 x KCHV070/KDHV070 7kw one on one Ducteds

Controls:

• 129 x XE70 Wall Controllers

Outcome

- Corrosion Resistance: Black fin coil protection significantly improved durability in the coastal environment

- Space-Saving Design: Bulkhead units fit neatly within wardrobes, preserving interior aesthetics

- Cost Efficiency: The solution delivered strong ROI for the developer through reduced maintenance and installation costs

- Proven Reliability: System performance has been validated in similar Australian coastal installations

- Design Flexibility: Long piping lengths enabled optimal condenser placement withoutcompromising system efficiency

More info about Braemar can be found visiting our Braemar page.

For specific product information, visit our, VRF Air Conditioning Commercial Products.

Installer details, Cold Front.

HVAC Case Study Overview

Industry

Education Facilities & Offices

Country

Australia

Region

Queensland

Technology

VRF/Reverse Cycle Heating & Cooling

Application

Heating and Cooling

Brand

Braemar