Direct Evaporative Cooling

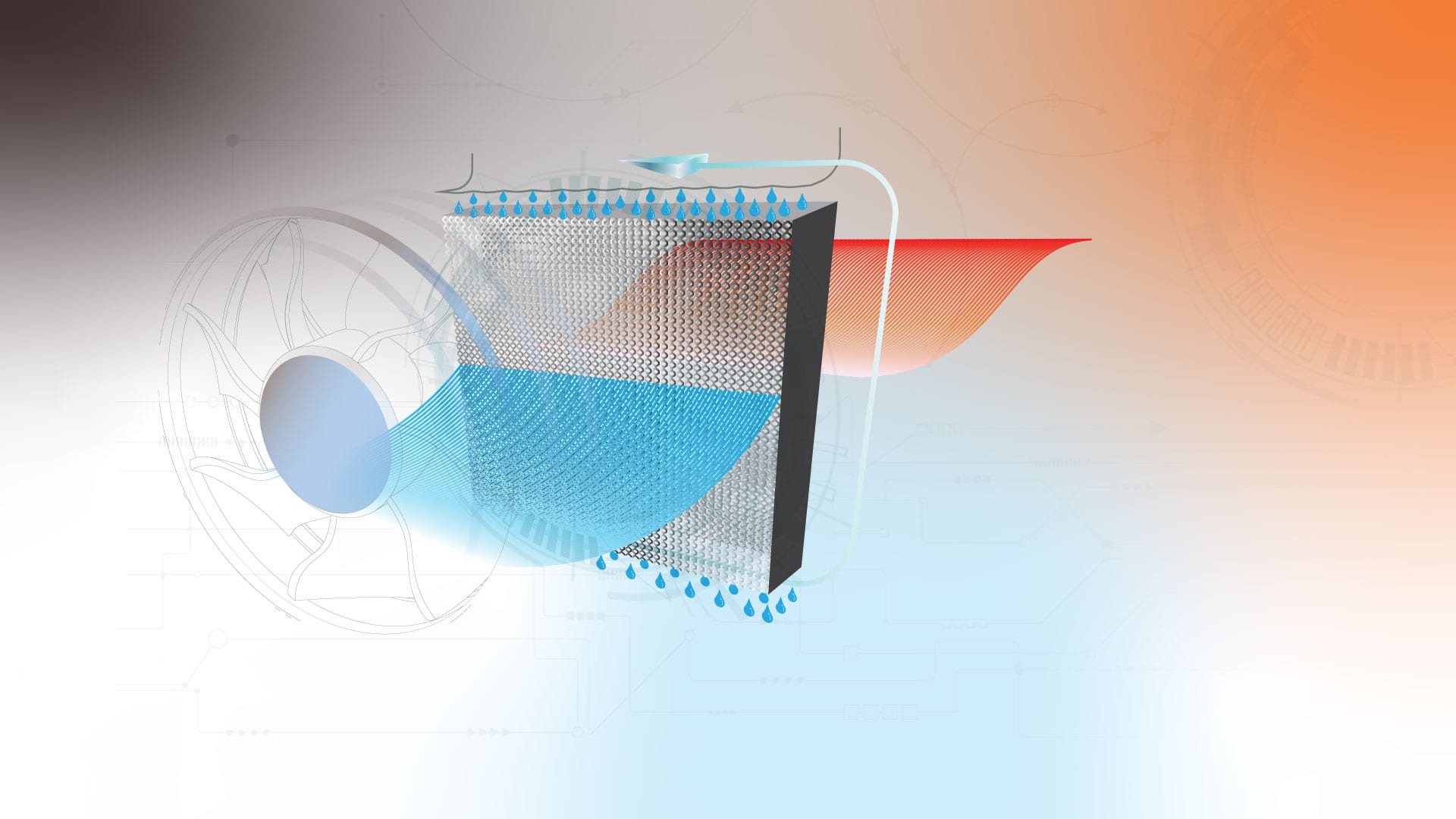

Coolair evaporative cooling uses evaporation to cool the air. Based on the principles of evaporation, hot and dry outside air is drawn through water-soaked cooling pads. As the air is pulled through these pads, the water evaporates and the heat in the air is absorbed, which lowers the air temperature. A fan then pushes the cool air throughout the building via a network of ducts.

The key to effective evaporative cooling is to ensure saturation of all cooling pads during operation and to size and design the system’s fan and motor to deliver the appropriate airflow for the space.

Evaporative cooling describes this natural phenomenon, however, there are many other terms that we might hear with the same meaning including evaporative air conditioning, adiabatic cooling, ducted evaporative cooling, swamp coolers, and desert coolers.

Coolair solution

Coolair by Seeley International offers full series of cost-effective evaporative cooling solutions.

Whether you need cooling for small or large commercial applications, industrial plants, our Coolair brand provides energy-efficiency, fresh air and value-for-money cooling solutions. Seeley International never stops striving to innovate and build the world’s most energy efficient products: evaporative cooling is fast becoming the most efficient option when cooling large or open-air spaces.

You can never go wrong when choosing Coolair evaporative cooling: Seeley International uses its NATA laboratory for accredited tests results to substantiate superior performance against competitive products and systems.

Find a distributor in your countryHow does it work?Explore the benefits

Coolair CPQ 1100X

Cost effective adiabatic cooling for big areas

Discover the key features

- 10,120 m3/h airflow (Industry standard, 80 Pa)

- Axial fan

- PSC motor

- 14.1 kW Cooling Capacity

- 1.2 kW max power consumption

Coolair CPQ 700

Evaporative cooling for small buildings

Discover the key features

- 7,200 m3/h airflow (Industry standard, 80 Pa)

- Axial fan

- PSC motor

- 9.5 kW Cooling Capacity

- 870 W max power consumption

How does Coolair evaporative cooling work?

Evaporative cooling uses evaporation to cool the air.

Hot air enters the cooling unit on the roof where it is filtered and cooled as it passes through specially designed moistened Chillcel™ pads. As the air passes through the cooling pads, the water evaporates and the heat in the air is absorbed, which lowers the air temperature. Finally, a fan pushes the cool air throughout the building via a network of ducts.

Smart control suite

Seeley International has designed the most advanced technology to give you full control of your coolers in the smartest way. In fact, easy to connect, all products of the MagIQtouch® Controller suite are also easy to install & intuitive. Not just Supercool, but SuperSmart!

From the MagIQtouch touch screen controller, to the smart indoor and external air sensor, next generation control is available for your company. Moreover, you can connect the coolers to BMS system, for a full integration experience.

Explore control options

100% fresh air

The evaporative cooling process relies on airflow, with cool air entering through ducts and then exiting via open doors or windows or extract fans. For this reason, only 100% fresh air is circulating, rather than stale and recycled air.

Increased ventilation

Evaporative cooling is the perfect solution when cooling huge buildings, because of reduced running costs and high airflow. Indeed, it is the most suitable solution when traditional air conditioning is not an option.

Spot cooling

Often commercial or industrial buildings have small spaces that are hot and uncomfortable to work in (because of heat from machines for example). In these cases, Evaporative Cooling can blanket the hot spot with a flow of cool, high velocity, fresh air, designed to positively impact your workers whenever they are in that hot location.

Filtered air

As the fan draws outside air through the cooling pads, this air is not only chilled but also filtered from impurities.

Coolair and the environment

Reduced greenhouse gas emissions

Evaporative cooling uses water to cool. This helps reduce the production of greenhouse gases, including harmful hydroflourocarbons.

Energy efficient

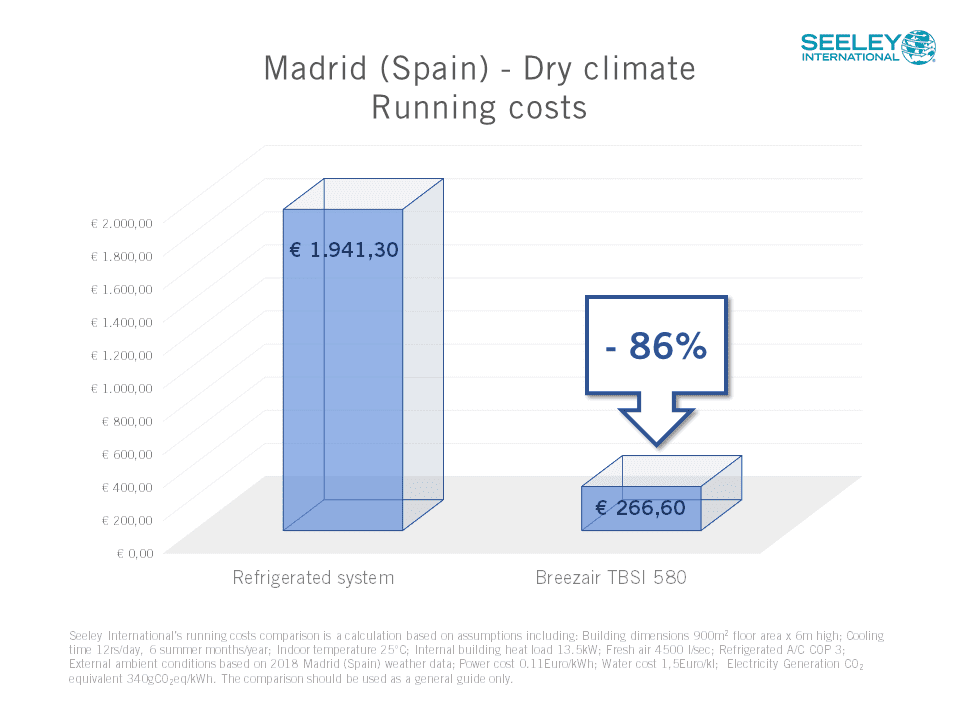

Better for your pocket and for the environment. We have estimated that in a location like Madrid (Spain) using a Seeley evaporative cooler you can reduce running costs up to 86%1 and carbon emissions up to 90%2.

Minimal water usage

The technologically advanced water management system continuously checks the quality of the water in your cooler. The system automatically replaces the water when mineral deposits exceed an acceptable level. The optimal result: minimum water use for maximum, fresh cooling power. Furthermore, you can generate your own cooling medium by rain water harvesting and to create a water neutral solution, you can use the waste water for grey, fire or irrigation.

Coolair annual running costs very low

When cooling large areas, the best option you can use is by far evaporative cooling, especially for industrial and commercial spaces. Air conditioning is not such a viable option, because in warehouses or industrial plants, the capital and running costs would be extremely prohibitive for end-users.

With increasing energy prices, and extreme temperatures making summer longer and hotter, evaporative cooling has a significant and increasing edge on direct expansion air conditioning when it comes to energy efficiency, performance and carbon impact.

In addition, we have estimated that using a Seeley International axial inverter evaporative cooler, you can save up to 86%1 on running costs over refrigerated air conditioning system performing the same duty, in a locationin Central Europe.

Madrid, SPAIN (Dry Climate) Running costs comparison (A/C vs Evaporative Cooling)1

A wide range of applications for Coolair Evaporative Cooling

Most industries with high heat loads, such as printing, ceramics, glass, rubber or electronics, have no cooling system installed, and this impacts on the workers’ morale and productivity, as well as on their health. Furthermore, in cases where they have traditional cooling systems installed, they rely on recirculating the air in the indoor space, which can be full of fumes and germs. Finally, premises such as warehouses or big storage rooms, especially when dealing with food and pharmaceutical products, have specific requirements of temperature.

In all these examples, Direct Evaporative Cooling could be the right solution. Evaporative Coolers do not use any sort of chemical refrigerants to cool the air, just a water pump to supply water to the wetted media where evaporation occurs and electrical power for the fan that pushes the cooled air inside the building. Many companies in Europe have already given trust to Evaporative Cooling: printing facilities, electronic manufacturing industries, automotive assembly lines and showrooms, ceramics, food industries, warehouses.

In addition, since Coolair evaporative cooling needs to extract stale air from inside the building, it is also suitable for semi-open spaces, such as car workshops, terraces or tents for events.

Coolair evaporative cooler delivers 100% fresh air

Evaporative cooling delivers a natural, exceptionally healthy cooling experience in the place where people spend most of their time, at work. It uses a fan to push outside air through water-soaked cooling pads to bring an endless supply of cool, fresh filtered outside air into the building, leaving moisture in the air, which combats dehydration and illnesses such as asthma.

Building ventilation is becoming a concern for all businesses, to ensure indoor air quality is maintained. Business owners need to guarantee a safe workplace for employees and minimize risk of contamination for all patrons. Therefore, we have collected the latest Covid-19 containment guidance from most important independent associations, to explore requirements and suggestions. If you are interested to see how evaporative cooling, no recirculation and fresh air can decrease the risk of transmission, you can read our article here3: https://www.seeleyinternational.com/eu/news/building-ventilation-and-covid-19-containment-guidances/

[1] Seeley International’s running costs comparison is a calculation based on assumptions including: Building dimensions 900m2 floor area x 6m high; Cooling time 12rs/day, 6 summer months/year; Indoor temperature 25°C; Internal building heat load 13.5kW; Fresh air 4500 l/sec; Refrigerated A/C COP 3; External ambient conditions based on 2018 Madrid (Spain) weather data; Power cost 0.11Euro/kWh; Water cost 1,5Euro/kl; Electricity Generation CO2 equivalent 340gCO2eq/kWh. The comparison should be used as a general guide only.

[2] Seeley International’s carbon emissions comparison is a calculation based on assumptions including Building dimensions 900m2 floor area x 6m high; Cooling time 12hrs/day, 6 summer months/year; Indoor temperature 25°C; Internal building heat load 13.5kW; Fresh air 4500 l/sec; Refrigerated A/C COP 3; External ambient conditions based on 2018 Madrid (Spain) weather data; Electricity Generation CO2 equivalent 340gCO2eq/kWh. The comparison should be used as a general guide only.